Categories

- animatronics (12)

- apple (11)

- arduino (179)

- art (41)

- articles (121)

- artificial intelligence (11)

- automation (421)

- avr (205)

- bitcoin (3)

- breadboard (9)

- cameras (57)

- cars (26)

- cell phones (28)

- clothing mods (21)

- console mods (26)

- dangerous (94)

- desktop mods (24)

- embedded (5)

- flying things (54)

- fpga (22)

- gaming creations (108)

- interface (225)

- internet (17)

- laptop mods (6)

- lasers (22)

- linux (7)

- magnetic (3)

- medical (12)

- microcontrollers (51)

- misc projects (152)

- msp (12)

- music (124)

- pic (90)

- projects (23)

- pyroedu (76)

- raspberry pi (26)

- robots (312)

- security (36)

- sensors (307)

- software (200)

- solar (19)

- stamp (9)

- tools (149)

- tutorials (98)

- Uncategorized (45)

- usb (44)

- wireless (256)

Sponsors

Posted July 21, 2015 by Chris

"On this site we have published complete directions on how to make your own sentry gun, which autonomously tracks, aims, and shoots at targets…We are a unique project in that everything we do is completely open-source. This includes 100% of our code, as well as our electrical schematics, and even the CAD design files for our Standalone Controller. Our system has been used on six continents and in more than 20 countries (so far), and is even used by the Australian Navy in their training program."

Posted July 19, 2015 by Chris

"The Haptic Appointment Manager manages all of an individual’s appointments, ensuring they arrive on time and in the right location by subtly guiding them throughout the day.

This system uses a GPS receiver and a compass to maintain awareness of its absolute and rotational position. By interfacing with a calendar of time stamped waypoints, this system effectively guides the user to his appointments by vibrating in the direction of the next waypoint."

Posted July 13, 2015 by Chris

"Last weekend brought an interesting challenge: to create a remote-controlled, small-sized dry ice ‘fog’ dispenser for a company event. In the end it wasn’t used, but I had a lot of fun building it anyway. Here is how it was done…"

Posted June 24, 2015 by Chris

"This animatronic plant was originally created for a local production of Little Shop of Horrors. I ‘repurposed’ it for a local library’s summer reading program in 2008. The narration was recorded using Sound Forge and the soundtrack was produced in Acid. All was done in house at Sleeping Dragon Studios, Ltd."

Posted June 19, 2015 by Chris

"These devices work by having a infrared LED on one end of the slot and a phototransistor at the other end. There are transistor like devices in the catalogs and there are logic devices as well. Since the current flows when the light is blocked I assumed this was a logic based device and not just a raw optotransistor for the sensor."

Posted May 23, 2015 by Chris

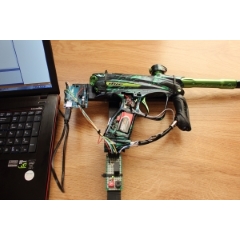

"Now I continue the ‘Out of Boredom’ series with a setup that allows firing a paintball marker (gun) with a command sent from a computer 🙂 This time software stack is simpler – just a small Arduino sketch and uncomplicated WinForms (.NET/C#) application, but hardware requires a bit of electronics knowledge."

Posted May 17, 2015 by Chris

"This part will describe all the hardware and various techniques used to figure out which signal goes where. Why do this? It’s an improvement on the original firmware and an exercise in consumer product design."

Posted May 4, 2015 by Chris

"A ballistic chronograph is used to detect the speed of a projectile shot through a sensor port. The simplest type of chronograph design is based on finding the average speed of the projectile between two ports. This is as easy as dividing the distance between the two sensor ports with time taken to travel between the ports."

Posted April 29, 2015 by Chris

"This project falls purely into the ‘because I can!’ category – I was poking around the internet one day looking for a Cray emulator and came up dry, so I decided to do something about it. Luckily, the Cray-1 hardware reference manual turned out to be useful enough that implementing most of this was pretty straightforward. The Cray-1 is one of those iconic machines that just makes you say ‘Now that‘s a super computer!’ "

Posted April 27, 2015 by Chris

"All parts were developed separately. This allowed adjustments in the assembly as well as smaller changes in case the design of one or other part become required. Focus on low cost and use of materials easily accessible in the local market."