Categories

- animatronics (12)

- apple (11)

- arduino (179)

- art (41)

- articles (121)

- artificial intelligence (11)

- automation (421)

- avr (205)

- bitcoin (3)

- breadboard (9)

- cameras (57)

- cars (26)

- cell phones (28)

- clothing mods (21)

- console mods (26)

- dangerous (94)

- desktop mods (24)

- embedded (5)

- flying things (54)

- fpga (22)

- gaming creations (108)

- interface (225)

- internet (17)

- laptop mods (6)

- lasers (22)

- linux (7)

- magnetic (3)

- medical (12)

- microcontrollers (51)

- misc projects (152)

- msp (12)

- music (124)

- pic (90)

- projects (23)

- pyroedu (76)

- raspberry pi (26)

- robots (312)

- security (36)

- sensors (307)

- software (200)

- solar (19)

- stamp (9)

- tools (149)

- tutorials (98)

- Uncategorized (45)

- usb (44)

- wireless (256)

Sponsors

Build Like A Pyro!

Find many of the parts used on this site at our favorite online electronics shop

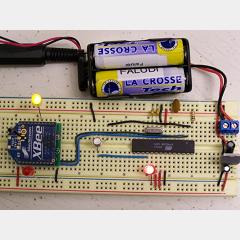

Wireless Arduino Programming

Posted August 14, 2008 by Chris

In what is probably a fairly obvious and easy thing to do with Xbee, we have the arduino wireless programmer. This is a pretty cool idea because it clears up the mess of wires around your project and is very simple integrated into your project.

2 Responses to “Wireless Arduino Programming”

Leave a Reply

Currently Hot

Advanced VGA On A UP2

make even cooler stuff appear on your monitor

The Accelerometer

take input from an accelerometer and show some ouput

L298 Stepper Motor Control

control a stepper motor with the l298 (l298hn)

Creating VGA With VHDL

create vga signals with vhdl and the up2 board

The Music Equalizer Display

make your own music equalizer display with a pic

Animatronics

Recent Articles

Arduino DDS Shield

build your own arduino based analog signal generator

A Digital Multimeter In Review (Tenma 72-7735)

learn about your typical digital multimeter in review

The PIC Annoy PCB

build something to annoy your co-workers

Automate Your Life With Cron

learn how to use cron for computer automation

Web Scraping For Weather Updates

learn how to use php to scrape the web

Creating A Web Server In Linux

learn how to make a lamp web server in linux

Stepper Motor Control With A stepRocker TMCM-1110

learn how a commercial stepper motor controller works

Arduino To PIC Wireless Proximity Motor Control

control a motor with a distance sensor wirelessly

PIC to Arduino Wireless Communication via XBee

use xbee to make a pic wirelessly talk to an arduino

Motor Control via Infrared Distance Sensor

control a motor simply by waving your hand

November 22nd, 2010 at 10:07 am

MAKE EVERYTHING NEGITIVE ON THE INTERNET ABOUT YOUR COMPANY GO AWAY! PERMENANTLY BURRY NEGITIVE INFORMATION ABOUT YOUR COMPANY

February 23rd, 2012 at 12:29 pm

ÿþT